A butterfly valve is a valve that uses a rotating valve plate to cut off the flow in a pipeline. The function of a butterfly valve is more on cutting off the flow in the pipeline than a ball valve. Although it is also possible to use a butterfly valve to adjust the flow rate, however this can damage the valve plate more quickly, which can affect the sealing of the butterfly valve.

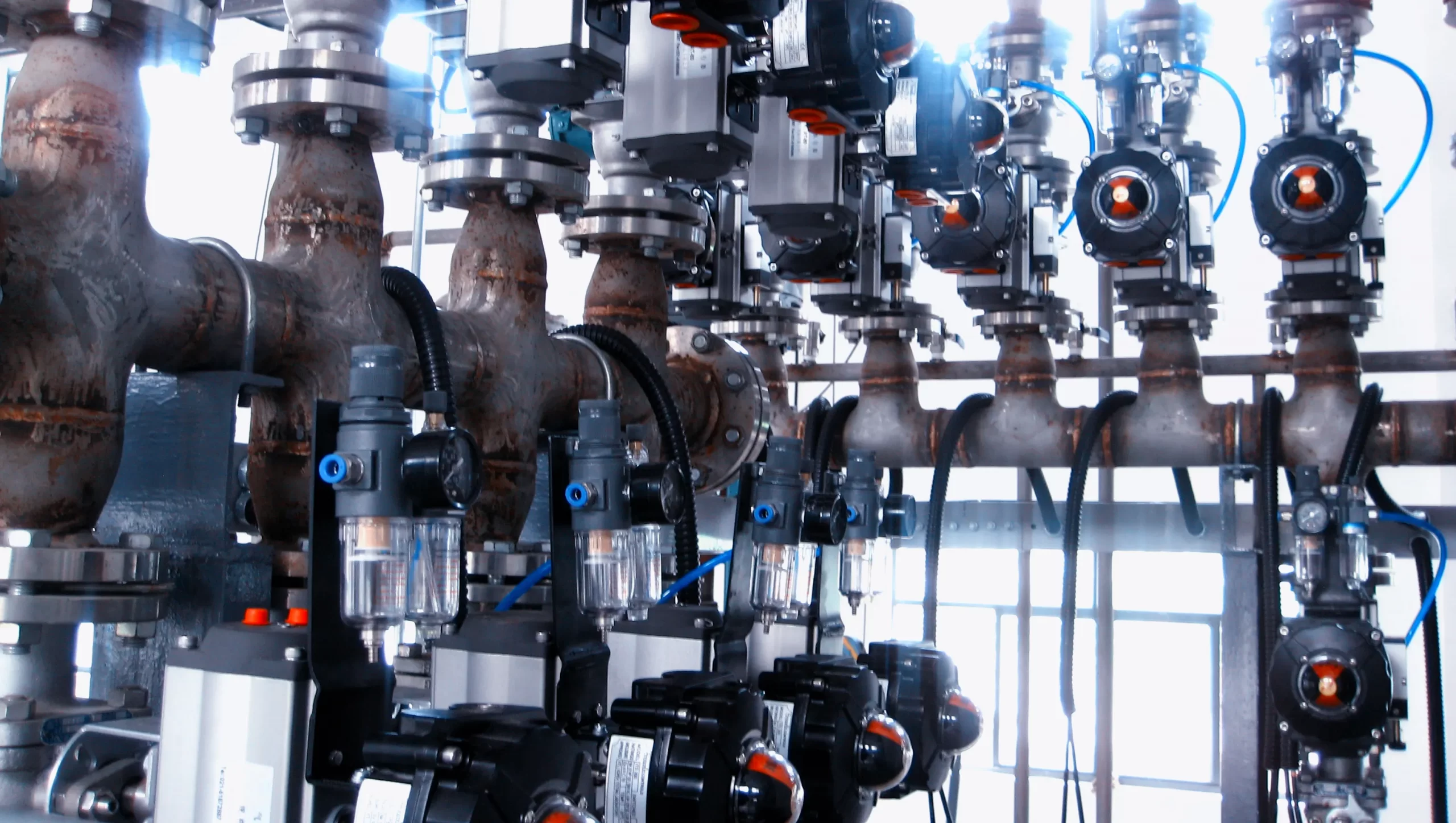

The butterfly valve is used in a wide variety of process media and industries especially in water supply, collection, and distribution, as well as pumping stations, and have a broad range of use cases especially in flow isolation. A couple of their key advantages over other valve families are their simple construction and compactness, resulting in the end products being of lighter weights and lower cost and with smaller installation footprints and faster actuation speeds.

- Butterfly valve parts

Below are the major butterfly valve components:- Valve Body

The valve body fits between the pipe flanges – the most common end connection types being flanged, double lug, and wafer types - Disc

Attached to the valve body is the disc that functions as a gate that stops or throttles fluid flow; it can be considered equivalent to a gate in a gate valve, or a ball in a ball valve. The disc is typically bored to receive the stem, or shaft. There are many variations in disc design, orientation, and material in order to improve flow, sealing, and/or operating torque.

- Seat

Lining the internal valve body is a strong elastomer or metal anti-leak seal that secures the disc in place in the closed position in order to achieve complete shutoff. - Stem

The valve shaft, often also referred to as the stem, is the component that connects the disc to the actuation mechanism and transmits the torque through itself. - Seals

Seals are present at multiple interfaces within the valve to either ensure a tight seal during operation or to isolate the process media from the valve’s internal components for a more flexible and cost-efficient design.

- Valve Body

- Butterfly valve: working principle

The construction of a butterfly valve is relatively simple, with the rotation of the valve disc controlling the fluid flow. In the closed position, the disc blocks the valve bore while in the open position, the disc is oriented perpendicular to the flow direction to allow flow. Butterfly valves generally provide bi-directional flow and shutoff capability. However, they are not full-bore, which renders them unsuitable for pigging or swabbing. The body material is ductile iron with an epoxy powder coat on both internal and external surfaces. The valves are typically operated by handwheels, gears, or actuators, or a combination thereof, according to the specific application requirement and technical specifications. - Butterfly valve actuation

There are multiple ways to operate or actuate, a butterfly valve – manual, semi-manual, or fully automatic.- Electric: Uses an electric actuator for controlling the valve with a 4-20mA control signal and is typically used for high-precision regulation and time-sensitive applications.

- Pneumatic: Also used for high-precision application and uses compressed air for actuation.

- Hydraulic: Typically used for applications requiring large torques for opening and closing the valve, such as high-pressure and high-viscosity applications.

- Manual: Manually operated butter valves make use of a handwheel, crank, or lever to operate the valve. Smaller manual valves are typically fitted with a lever. For larger sizes, handwheels are provided and are accompanied by a gearbox to transfer the torque with a high mechanical advantage. Another way of manual actuation is in use cases where the valve is buried underground without a manhole; in such applications, actuation is done with an extension spindle, adapter / square cap, and a corresponding T-key from the ground level.

Due to inherently lower torque requirements, sizing and installing actuators are less expensive for butterfly valves compared to others, like gate valves.

- Advantages of butterfly valves

Depending on the application, butterfly valves can offer significant advantages over other types of valves, especially for dimensions over DN 200 (200 mm) in size: -

- Lightweight and Compact: With a compact design and a smaller face to face dimension, butterfly valves have a considerably less installation footprint and offer savings in the form of lower installation costs including labour cost, equipment, and piping support.

- Low Maintenance Requirements: An inherently simple, economic design that consists of few moving parts, and hence fewer wear points, significantly reduces their maintenance requirements.

- Fast Acting: A 90° rotation of the handle, or the actuation mechanism, provides a complete closure or opening of the valve. However, with larger butterfly valves, a gearbox is often required as part of the actuation mechanism which reduces the operational torque and simplifies the operation of the valve but comes at the expense of speed.

- Low Cost: Owing to their simple design, butterfly valves require less material and are simpler to design and manufacture and are often the more economical choice compared to other valve types. The cost savings are mainly realized in larger valve sizes, typically above DN 300.

- Versatility: Butterfly valves have a wide variety of use cases including the ability to be installed underground.

These above contents can give you a basic understanding of butterfly valves

Tags: Butterfly Valve

--- END ---