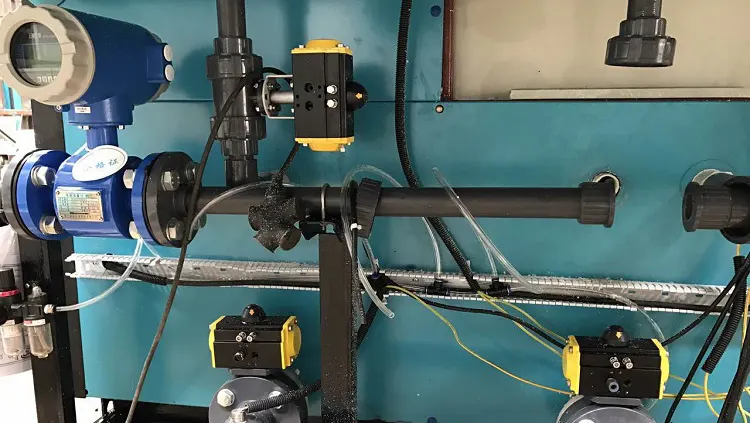

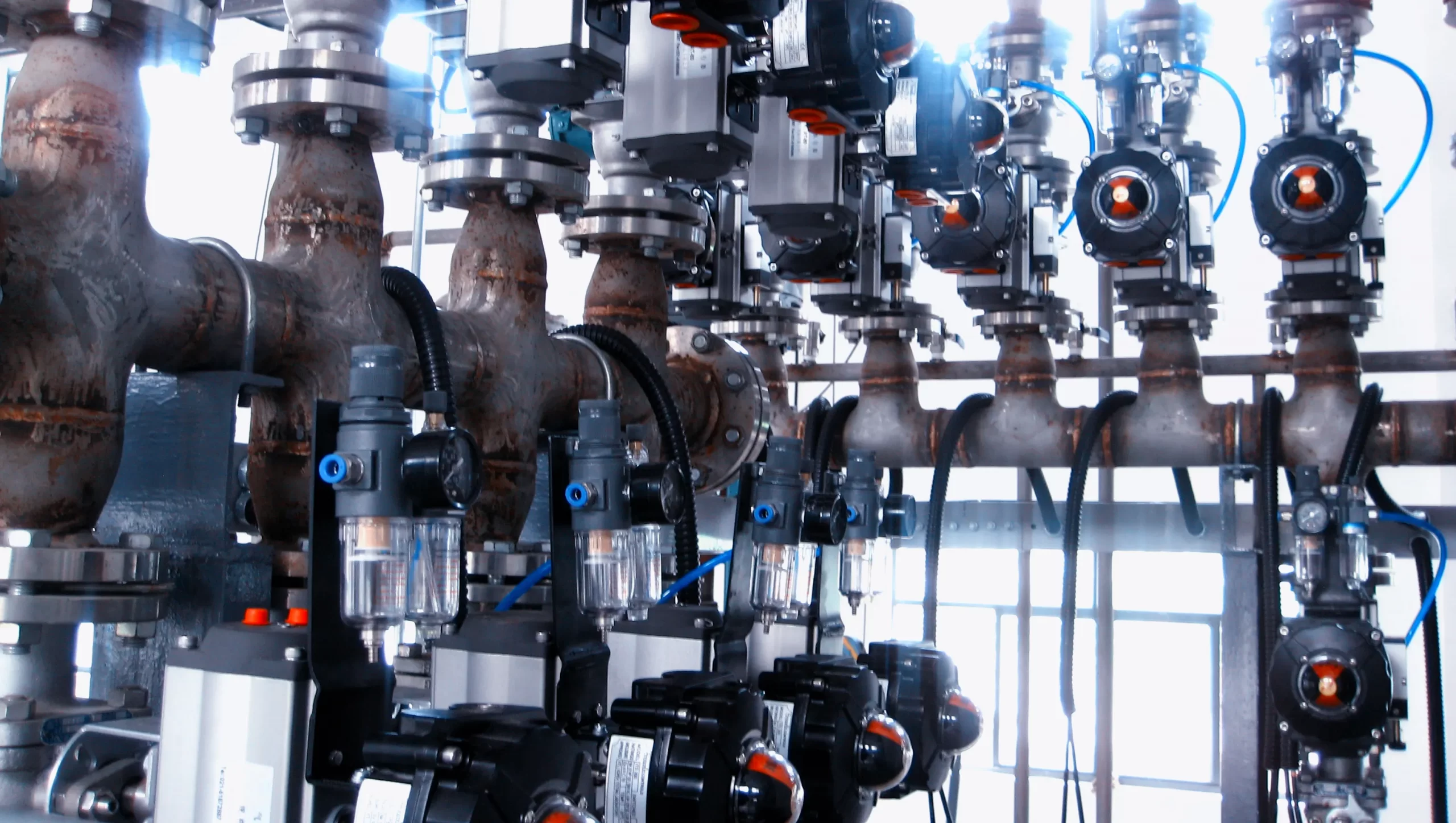

The actuator and adjustment mechanism of the pneumatic actuator valve are a unified whole, and the actuator has two types: membrane type and piston type.

The piston type has a long stroke and is suitable for occasions that require greater thrust; while the membrane type has a small stroke and can only directly drive the valve stem. Because the pneumatic actuator has the advantages of simple structure, large output thrust, stable and reliable action, and safety and explosion protection, it has a wide range of applications in power plants, chemical industries, oil refining and other production processes with high safety requirements.

The main advantages of pneumatic actuators:

- Receive continuous air signal and output linear displacement (after power-on/air conversion device, continuous electrical signal can also be received), and some can output angular displacement with rocker arm.

- There are positive and negative functions.

- The moving speed is high, but the speed will slow down when the load increases.

- Output force is related to operating pressure.

- High reliability, but the valve cannot be maintained after the air supply is interrupted (it can be maintained after adding a retaining valve).

- Inconvenient to achieve segment control and program control.

- Simple maintenance and good adaptability to the environment.

- Larger output power.

- With explosion-proof function.

Tags: pneumatic actuator

--- END ---