–General Introduction–

An angle seat piston valve is a pneumatically-controlled valve with a piston actuator providing linear actuation to lift a seal off its seat. They are used to regulate the flow of liquids, gases, steam, vacuum and even aggressive fluids. They can also operate with high temperatures and high viscosity media, even under zero differential pressures. The seat is set at an angle to provide the maximum possible flow when unseated. Therefore, they are excellent long-life alternatives to ball valves. These valves are also suitable alternatives for solenoid valves, especially with contaminated, viscous media where typical solenoid valves would fail

–Operation–

It uses a single acting pneumatic actuator with spring safety protection to operate the guide angle seat valve. When using, it should be normally open or normally closed.

The product is made of stainless steel and polytetrafluoroethylene. It can be used in most gas, liquid, steam and corrosive occasions. It has a radiator to protect the actuator. It ensures a long service life of the valve.

There are single acting and double acting. Single action (pneumatic head is usually a hole); working principle; according to the function of spring return to open and close, it is divided into normally open type and normally closed type. Double acting (pneumatic head usually has two holes); working principle: air supply controls its switch. (according to the customer’s requirements, double action plus spring return can also be selected for more accurate control).

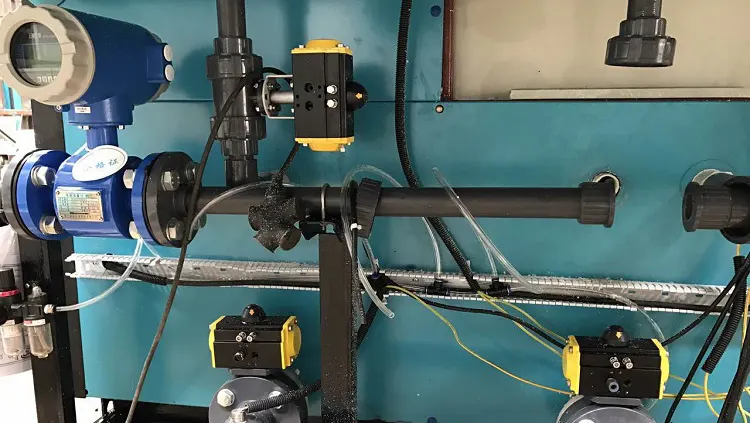

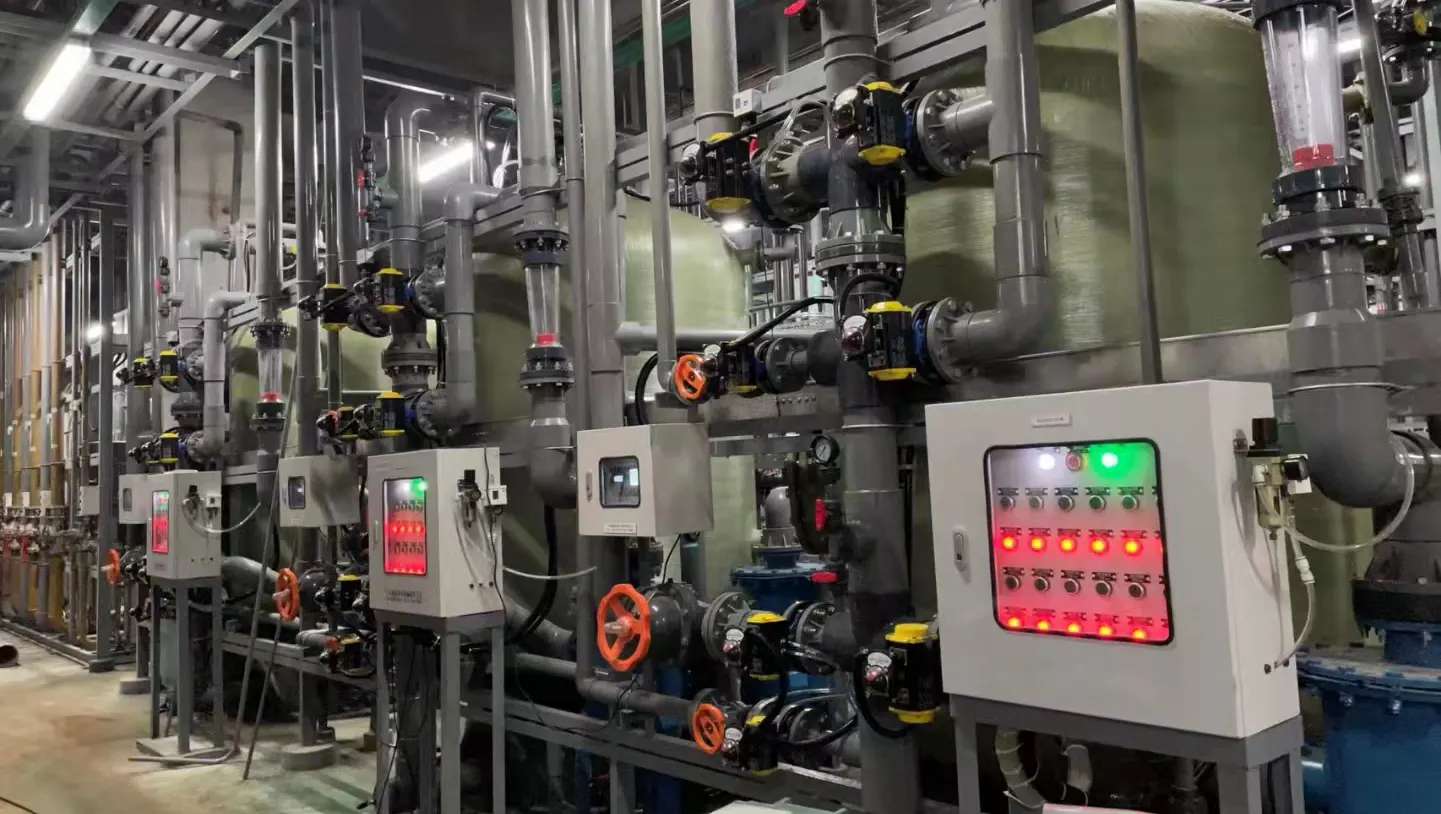

Pneumatically angle seat valve is widely used to start frequently in a short time. It can save space by keeping the flow rate. It has the characteristics of sensitive response and accurate action. Can be used with solenoid valve and pneumatic control can accurately control the flow of gas and liquid. It can meet the requirements of accurate temperature control and dripping liquid.

–Connection Types: Threaded connection, Tri-clamp connection, Flange connection, Welded connection

–Actuator Types: Plastic Actuator Angle Seat Valve, Stainless steel actuator angle seat valve

–Temperature Types: Normal temperature type (up to 200 degrees),

High temperature type (up to 300 degrees)

–Actual application parameters–

- Pressure range: 0-2.5Mpa (ie PN0-PN25)

- Medium temperature: -20 ℃ ~ +200 ℃ (normal temperature type) -20 ℃-+300 ℃ (high temperature type)

- Environment temperature: -10 ℃ ~+60 ℃

- Threaded pneumatic angle seat valve specifications: DN10-80

Quick assembly pneumatic angle seat valve specifications: DN15-80 - Flange pneumatic angle seat valve specifications: DN15-80

- All stainless steel pneumatic threaded (internal thread) angle seat valve: DN10-65

- All stainless steel pneumatic quick-fit angle seat valve: DN15-65

- All stainless steel pneumatic flange angle seat valve: DN15-80

- valve body material: stainless steel

- Sealing material: Teflon

- Actuator housing: polyamide press, stainless steel

- Control gas: neutral gas, air

- Control liquid: automated industrial control fluid, food grade dairy industry, domestic water, ordinary pipeline fluid medium, etc.

–Product Features–

- With valve open or closed position display.

- External pneumatic pilot can increase service life and is maintenance-free.

- There is a self-adjusting sealing gland between the overflow port and the slider to improve the sealing performance.

- The angle seat structure of the valve body can achieve large flow (especially compared with ordinary globe valves),

- Compact structure and fast response.

–Installation and Maintenance–

Must comply with applicable safety regulations

1. The pipeline must be clean and free of pollution.

2. Install as needed, but it is best to make the actuator face upward. Pay attention to the flow.

3. When connecting the valve, pay attention to aligning with the pipeline, and only remove the actuator when the user requires it.

4. Before opening or repairing the angle valve, cut off the fluid and control air source and reduce the pressure in the piping system.

–Note–

Features when choosing flow direction A:

1. When the flow direction is selected, the service life of the product can be increased.

2. When the working medium is liquid, select this flow direction to prevent hammer impact.

3. For products with a diameter of Φ15/Φ20/Φ25, the working pressure must be below 0.3MPa, otherwise, double

–Acting actuator–

For products with diameter Φ32/Φ40, the actuator must choose a double-acting Φ100 size.

For products with a diameter of Φ50, the actuator must choose a double-acting Φ125 size.

Features when selecting flow direction B:

When the working medium is steam or gas, when the flow direction is selected, the flow tightness of the product can be improved

Yes, but because the V-shaped sealing ring in the valve body is in contact with the working medium for a long time, it has a certain

In addition, when the working medium is liquid, it is not waterproof against hammer impact.

--- END ---