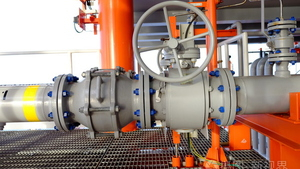

COVNA GROUP provide all types of gate valves, also can be equipped with electric actuator or pneumatic actuator.

The gate valves have the characteristics: Low fluid resistance Applicable pressure and temperature range, etc. It is one of the most commonly used cut-off valves, used to cut off or connect the medium in the pipeline.

Diameter shrinkage can reduce the size of parts, reduce the force required for opening and closing, and expand the application range of parts. But after the diameter shrinks, the fluid resistance loss increases.

Domestic and abroad low-pressure gate valves generally use cast iron materials. Cast iron gate valves often have serious problems such as freezing and cracking of the valve body and falling off of the gate. The carbon steel stem of the cast iron gate valve is easy to rust, the quality of the packing gasket is poor, and the internal and external leakage is serious.

The PN10 low-pressure carbon steel gate valve produced by COVNA GROUP Valve Factory replaces the traditional iron gate valve, effectively solving the problems of the cast iron gate valve shell being easy to freeze and crack, the gate is easy to fall off, the valve stem is easy to rust, and the sealing performance is unreliable.

So more features of gate valves:

1. Light weight: The body is made of high-grade nodular black cast iron, and the weight is about 20%~30% lighter than the traditional gate valve. It is easy to install and maintain.

2. Overall rubber encapsulation: The gate adopts high-quality rubber for the overall inner and outer rubber. European first-class rubber vulcanization technology enables the vulcanized gate to ensure accurate geometric dimensions, and the rubber and ductile cast gate can be firmly connected, which is not easy Good shedding and elastic memory.

3. Flat-bottomed gate seat: The traditional gate valve often deposits in the groove at the bottom of the valve due to foreign objects such as stones, wood, cement, iron filings, sundries, etc. after the pipe is washed with water, which can easily cause water leakage.

The bottom of the elastic seat-sealed gate valve adopts the same flat-bottom design as the water pipe machine, which is not easy to cause debris siltation and makes the fluid flow unimpeded.

4. Precision casting valve body: The valve body adopts precision casting, and the precise geometric dimensions make the inside of the valve body without any fine processing to ensure the sealing of the valve.

5. Small fluid resistance: because the internal medium channel of the gate valve body is straight, the medium does not change its flow direction when flowing through the gate valve, so the fluid resistance is small.

6. The opening and closing torque is small, and the opening and closing is more labor-saving. Because the direction of the gate movement is perpendicular to the direction of the medium flow when the gate valve is opened and closed, the opening and closing of the gate valve is more labor-saving

Tags: gate valve featutres

--- END ---