Gate valves and ball valves are the most commonly used flow control valves in the market. They are generally used to control the flow of liquid and gases. We explain the difference between them in terms of how they work.

Different operation

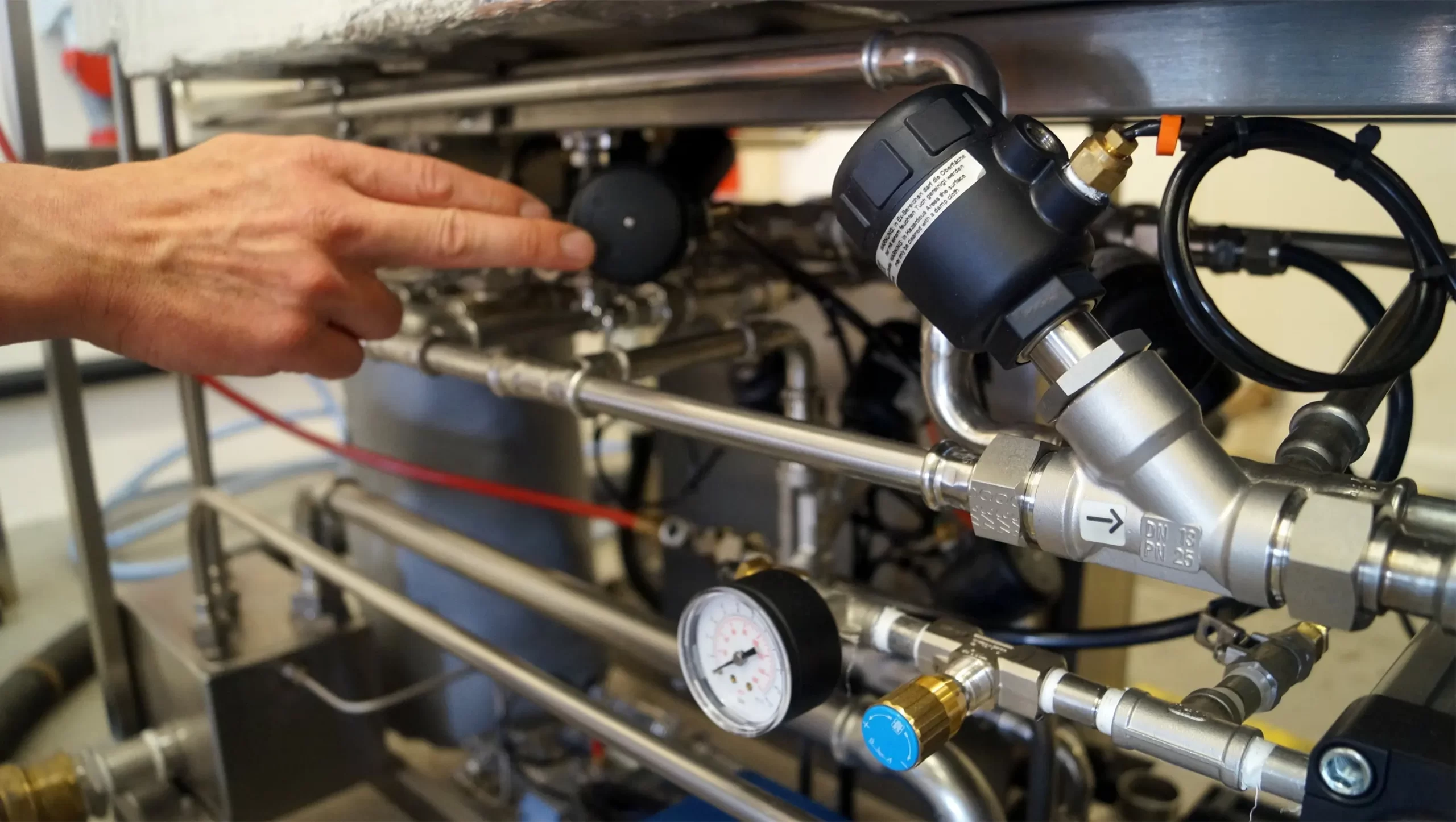

A ball valve uses a rotary ball with a bore and a stem. When the handle attached to the stem is turned, it rotates the ball to open or close the valve. This valve is also called a quarter turn valve because the handle only needs a 90° turn (quarter turn) to allow or block the flow of the media. The valve is open when the handle is parallel to the pipe and it is closed when the handle is perpendicular to the pipe.

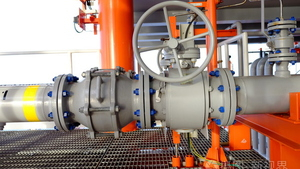

A gate valve uses a valve plate to control the flow of the media. A gate is a solid disk structure that is connected to the stem. The gate is lifted to open the valve and is returned down to its original position to close the valve. The valve is accompanied by a bonnet which when rotated controls the position of the gate. This valve is also called a multi turn valve because it takes more than a 360° turn to fully open or close the valve.

Advantages and Disadvantages

Due to the differences between gate and ball valves operation and design, there are certain advantages and disadvantages to each.

| Ball valve | Gate valve | |

| Shut off mechanism | Fast shut-off with only a quarter turn (90° turn) to close the valve. | Slow shut off as it requires more than a 360° turn to shut off the valve. |

| Water hammer | Fast opening and closing may cause water hammer*. | Slow opening and closing reduces the risk of water hammer*. |

| Visual detection | Open or closed state of valve can be visually detected with position of the handle. | Difficult to detect the open or closed state of valve. |

| Installation space | Requires more space than a gate valve to accommodate for quarter turn handle. | Requires relatively less installation space than a ball valve. |

| Leakage | Provides tight seal even if used after a long period of time. | More prone to leaks than a ball valve. |

| Durability | Durable and less prone to damage | Valve stem can be prone to corrosion making the valve less durable. |

*If the flow is abruptly stopped by rapidly shutting off the valve, pressure builds up due to the momentum of the moving medium and this causes a short pressure surge. The pressure surge causes a noise which sounds like the pipes were struck by a hammer. A powerful water hammer can cause a rupture or leak in the system.

Selection criteria

The following criteria can be considered before selecting between a ball valve and gate valve:

- Ports: A gate valve has 2 ports, while a ball valve can have more than 2 ports.

- Flow Capacity: A gate valve can provide larger flow capacity than a ball valve as they are typically offered in larger diameters.

- Opening and closing speed: A ball valve is better suited for applications that require faster opening and closing speed or during emergencies due to its quarter turn on/off operation. A gate valve requires more than a 360° turn, making it slower than a ball valve to operate.

- Sealing: A ball valve provides a tight seal and has complete shut off characteristics as compared to a gate valve. Therefore, ball valves are better suited for applications like natural gas where a proper seal long-term is important.

- Pressure: Both ball valves and gate valves are suitable for low pressure applications. However, for high pressure applications a gate valve is better suited. This is due to the fast opening/closing of the ball valve that may cause a water hammer.

- Connection: The choice of connection to the pipe is an important factor for both valves.

Common applications

Both ball valves and gate valves are commonly used in residential and industrial applications.

- Gate valves are generally found in older plumbing systems and in applications where frequent shut off is not required. Large water supply lines use gate valves due to their straight flow path and less flow restrictions. Ball valves are increasingly used in new plumbing systems with frequent shut off requirements.

- Gate valves are used for application with slurries and viscous media because they are easier to clean and maintain. Ball valves are not desirable because they are difficult to clean, and the slurry particles may damage the rotary ball.

- Gate valves are used in power plants, mining and water treatment applications which are high temperature and high-pressure environments.

- Ball valves are commonly used in fire protection systems and marine applications. They are best not used in food, beverage and pharmaceutical applications as ball valves are difficult to clean and may cause contamination.

Tags: Ball valve, Gate Valve

--- END ---