The valve type commonly used in sewage treatment engineering is a device that is installed in the middle of the pipeline to control the flow of fluid in the pipeline or the on-off of the fluid conveyed in the pipeline. Valves commonly used in sewage treatment include gate valves, butterfly valves, ball valves, and check valves.

1. Gate valve. The gate valve is composed of a valve body, a gate, a seal, and an opening and closing device. The opening and closing of the gate valve is completed by the reciprocating translation of the gate. The flow diameter of the gate valve is generally 50~1000 mm. When the valve is fully open, the passage is completely free of fluid. When passing the gate valve, the resistance is minimal, and it is suitable for passing sewage and sludge with high impurity content.

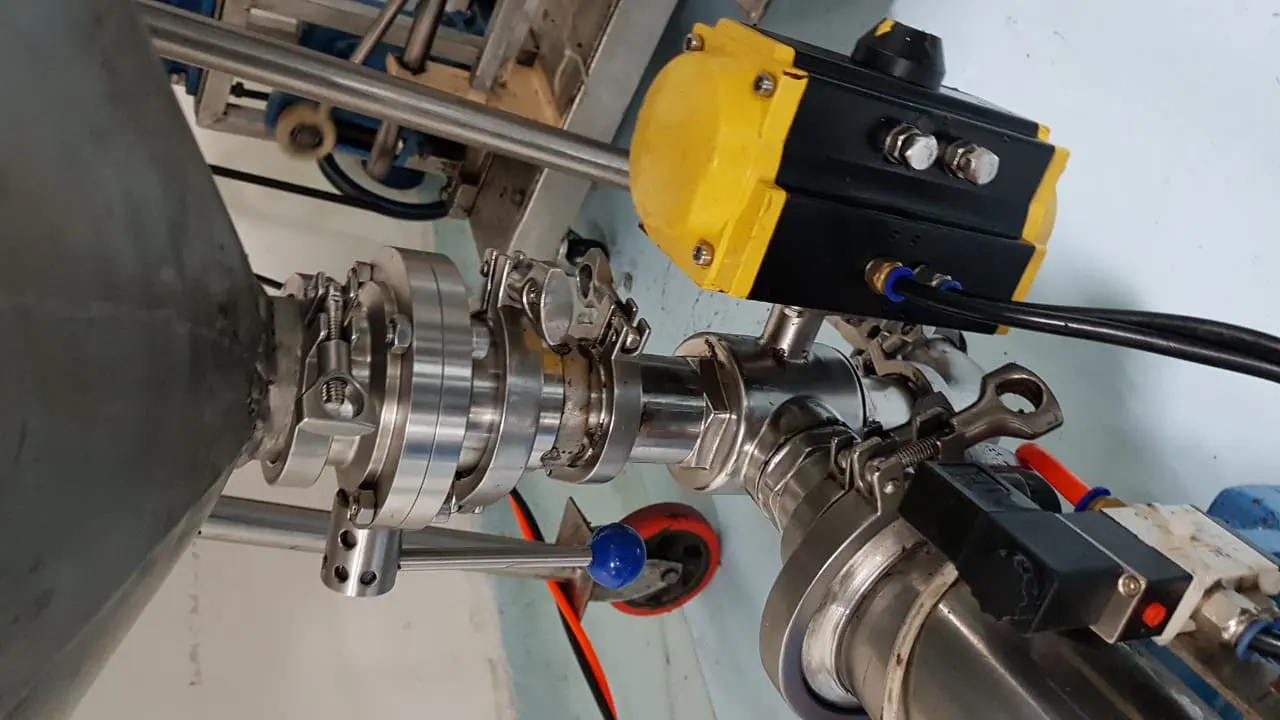

2. Butterfly valve. The butterfly valve is composed of a valve body, an inner lining (butterfly plate sealing device), a disc plate (a device to prevent fluid flow), and an opening and closing mechanism (a device that starts the rotation of the disc plate). The opening and closing of the butterfly valve is mainly realized by the 90° rotation of the disc. When the disc is turned to be perpendicular to the flow pipe, the butterfly valve is closed, and when the disc is turned to be parallel to the flow pipe, the butterfly valve opens. The main advantage of the butterfly valve is that it has a good seal. The disadvantage is that after the valve is opened, the butterfly plate is still in the middle of the circulation pipe, which has resistance to the flow of liquid in the circulation pipe.

3. Ball valve. The spool of the ball valve is a sphere. The center of the sphere has a channel that can be the same as the flow pipe. The opening and closing of the ball valve is realized by the rotation of the spool of the ball. When the channel on the ball spool is parallel to the direction of the flow pipe, the ball valve opens; when the channel on the ball spool is perpendicular to the direction of the flow pipe, the valve is closed. The main advantages of ball valves are good airtightness and good pressure resistance (withstand pressure of 20 MPa). The disadvantage is that compared with gate valves and butterfly valves of the same diameter, the volume and quality of ball valves are large, and the corresponding cost is higher.

4. Check valve. The main function of the check valve is to prevent the liquid from flowing back. Its working principle is that when the fluid flows in the forward direction, the valve spool is fully opened under the impact of the fluid. When the fluid flows in the reverse direction (backflow), the valve spool is under the reverse pressure of the fluid. Close to prevent backflow of fluid. For example, in the aerobic tank, when the aerobic tank fails and the aeration stops, in order to prevent the mud-water mixture in the aerobic bioreactor from being poured back to the air pump along the aeration tube, a check valve can be installed on the aeration tube.

Gate valves and butterfly valves are mostly used in sewage treatment engineering pipelines, and ball valves are rarely used.

--- END ---