1. For valves driven by gears and worm gears, the transmission mechanism should be inspected and cleaned according to the following requirements:

- Worm and worm gear should mesh well, work lightly, and have no jamming or excessive wear;

- The gear meshing surfaces and bearings of the open mechanism should be cleaned and filled with grease;

- For valves with closed mechanisms, 10% and no less than one should be spot-checked. The parts of the mechanism should be complete, the internal parts should be clean and free of dirt, the transmission parts should be free of burrs, and the gaps and meshing surfaces of each part should meet the requirements. Check the transmission mechanism one by one;

- If the lubricating oil is found to be deteriorated after opening the lid, replace the lubricating oil of the batch of valves.

2. For valves with sprocket mechanism, the center plane of the chain frame and the sprocket should be consistent. Check the working condition of the chain according to the working position. The chain movement should be smooth without falling out of the groove. The chain must not have any defects such as open loop, desoldering, corrosion, or sprocket and chain pitch mismatch

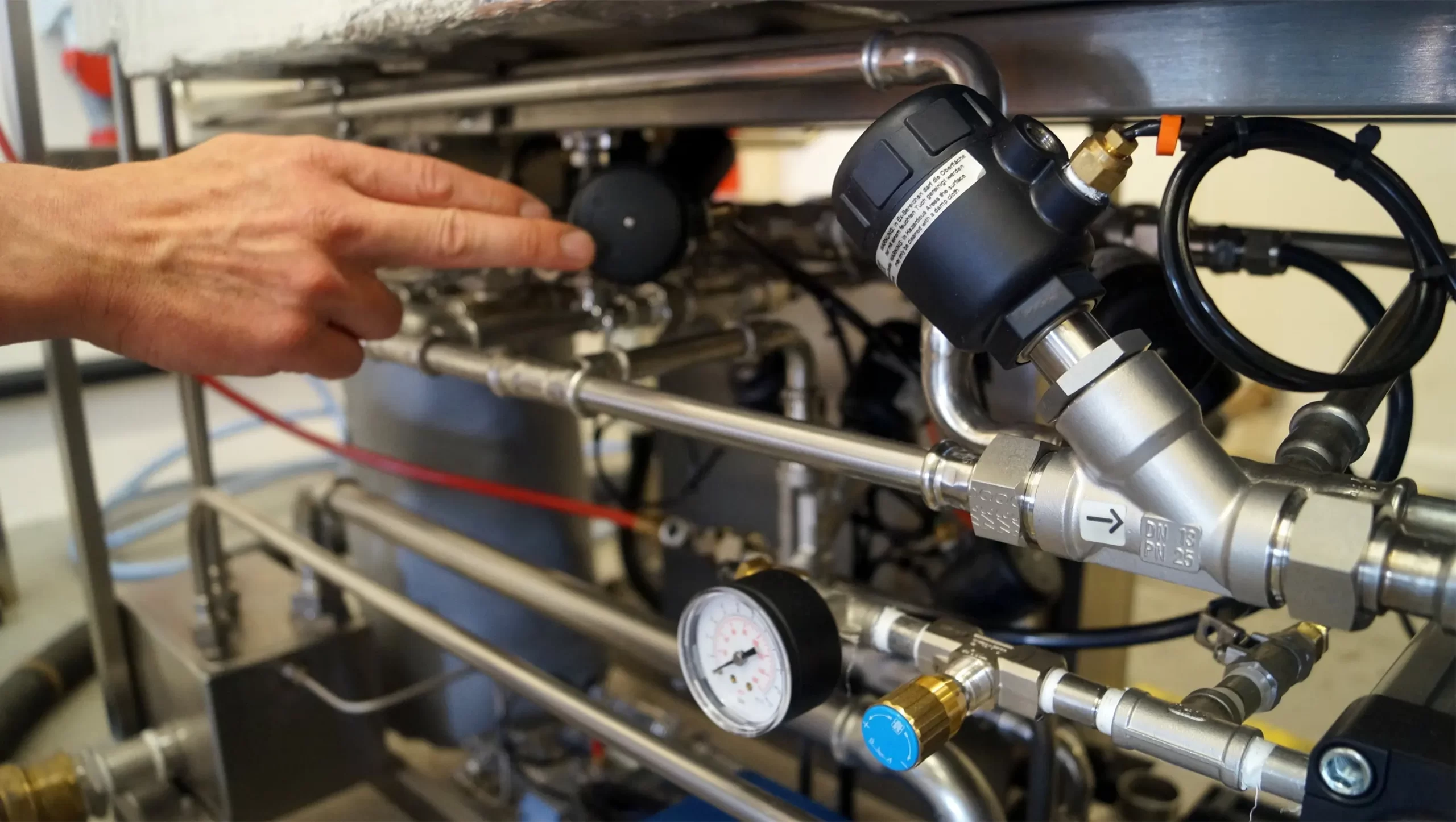

3. Valves driven by pneumatic or hydraulic pressure should use air or water as the medium, and carry out the opening inspection according to the working pressure of the piston. If necessary, the valve should be tested for sealing.

4. In addition to cleaning and inspecting the gearbox of the electric valve in accordance with the provisions of Article 1 of this regulation, the coaxiality of the coupling should be rechecked, and then the temporary power supply should be switched on, and the inspection should be carried out in the fully open or fully closed state. , Adjust the valve limit device, repeat the test no less than three times, the electric system should be reliable in action and accurate in instructions.

5. The electromagnetic valve should be connected to the temporary power supply, and the opening and closing test should be conducted, and it should not be less than three times. If necessary, the valve should be sealed under the closed state.

6. Valves with mechanical interlocking device should be tested and adjusted on the simulation frame of the installation position. The two valves should have coordinated opening and closing actions, light work, and accurate limit.

--- END ---