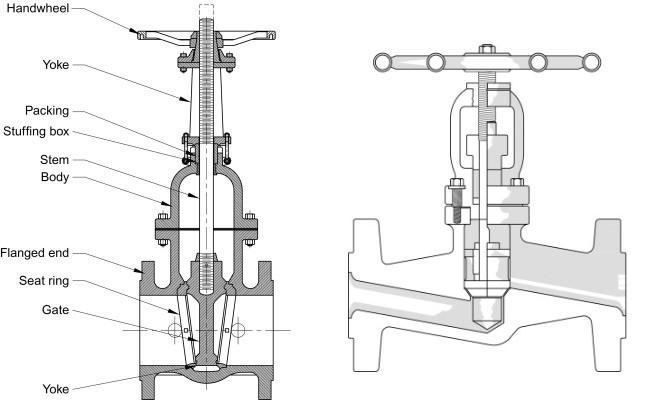

Globe valves, gate valves, butterfly valves, check valves and ball valves are now indispensable control components in various piping systems. Each valve is different in appearance, structure and even functional purpose. However, the globe valve and gate valve have some similarities in appearance, and both have the function of cutting off in the pipeline. Maybe some people will get confused when first know it. Let’s me introduce the differences to you.

Structure:

Attention should be paid to the selection of valves when the installation space is limited. The gate valve can be tightly closed with the sealing surface depending on the medium pressure, so as to achieve the effect of no leakage. When opening and closing, the valve core and the sealing surface of the valve seat are always in contact and rub against each other, so the sealing surface is easy to wear. When the gate valve is close to closing, the pressure difference between the front and back of the pipeline is large, which makes the sealing surface wear more serious.

The structure of the gate valve will be more complicated than that of the non return valve. From the appearance point of view, the gate valve is taller than the non return valve and the non return valve is longer than the gate valve in the case of the same caliber. In addition, the gate valve can be divided into bright rod and dark rod. The check valve does not.

Working principle:

When the check valve is opened and closed, the stem rises, that is to say, when the hand wheel is turned, the hand wheel will rotate and lift together with the stem. The gate valve rotates the hand wheel to make the valve stem move up and down, and the position of the hand wheel remains unchanged. The flow rate is different, the gate valve requires fully open or fully closed, but the globe valve does not. The globe valve has specified inlet and outlet directions; the gate valve has no inlet and outlet direction requirements.

In addition, the gate valve has only two states: fully open or fully closed, the gate opening and closing stroke is large, and the opening and closing time is long. The movement stroke of the valve plate of the non return valve is much smaller, and the valve plate of the non return valve can be stopped at a certain place during the movement for flow adjustment. The gate valve can only be used as a cut-off function and has no other functions.

Performance:

The globe valve can be used for cut-off and flow adjustment. The fluid resistance of the globe valve is relatively large, and it is more laborious to open and close, but because the distance between the valve plate and the sealing surface is short, the opening and closing stroke is short.

Since the gate valve can only be fully opened and fully closed, when it is fully opened, the flow resistance of the medium in the valve body channel is almost 0, so the opening and closing of the gate valve will be very labor-saving, but the gate is far away from the sealing surface and the opening and closing time is long.

Installation and flow direction:

The effect of the gate valve in both directions is the same. There is no requirement for the inlet and outlet directions for installation, and the medium can flow in both directions. The globe valve needs to be installed in strict accordance with the direction indicated by the arrow on the valve body. There is also a clear stipulation regarding the direction of the inlet and outlet of the globe valve. The “Three Chemicals” of the valve in my country stipulates that the flow direction of the globe valve is from top to bottom.

The non return valve is low in and high out. From the outside, it is obvious that the pipeline is not on the horizontal line of one phase. The gate valve flow path is on a horizontal line. The stroke of the gate valve is larger than that of the globe valve.

From the perspective of flow resistance, the flow resistance of the gate valve is small when fully opened, and the flow resistance of the load globe valve is large. The flow resistance coefficient of ordinary gate valve is about 0.08~0.12, the opening and closing force is small, and the medium can flow in two directions. The flow resistance of ordinary globe valves is 3-5 times that of gate valves (public number: pump steward). When opening and closing, it needs to be forced to close to achieve the seal. The valve core of the globe valve does not contact the sealing surface when it is completely closed, so the wear of the sealing surface is very small. Because the main force of the flow is large, the globe valve that needs an actuator should pay attention to the torque control mechanism Adjustment.

There are two ways to install the non return valve. One is that the medium can enter from below the valve core. The advantage is that the packing is not stressed when the valve is closed, which can prolong the service life of the packing and can bear pressure before the valve. Under the circumstance, the packing should be replaced; the disadvantage is that the driving torque of the valve is relatively large, which is about 1 times that of the upper flow, the axial force on the valve stem is large, and the valve stem is easy to bend. Therefore, this method is generally only suitable for small-diameter globe valves (below DN50). For globe valves above DN200, the medium flows in from above. (The electric check valve generally adopts the way that the medium enters from above.) The disadvantage of the way that the medium enters from above is just the opposite of the way to enter below.

Sealing:

The sealing surface of the globe valve is a small trapezoidal side of the valve core (see the shape of the valve core for details). Once the valve core falls off, it is equivalent to closing the valve (if the pressure difference is large, of course the closing is not tight, but the anti-reverse effect is not bad). The gate valve is sealed by the side of the valve core gate plate, the sealing effect is not as good as the globe valve, and the valve core will not be closed like the globe valve when the valve core falls off.

--- END ---