Advantages of pneumatic ball valve:

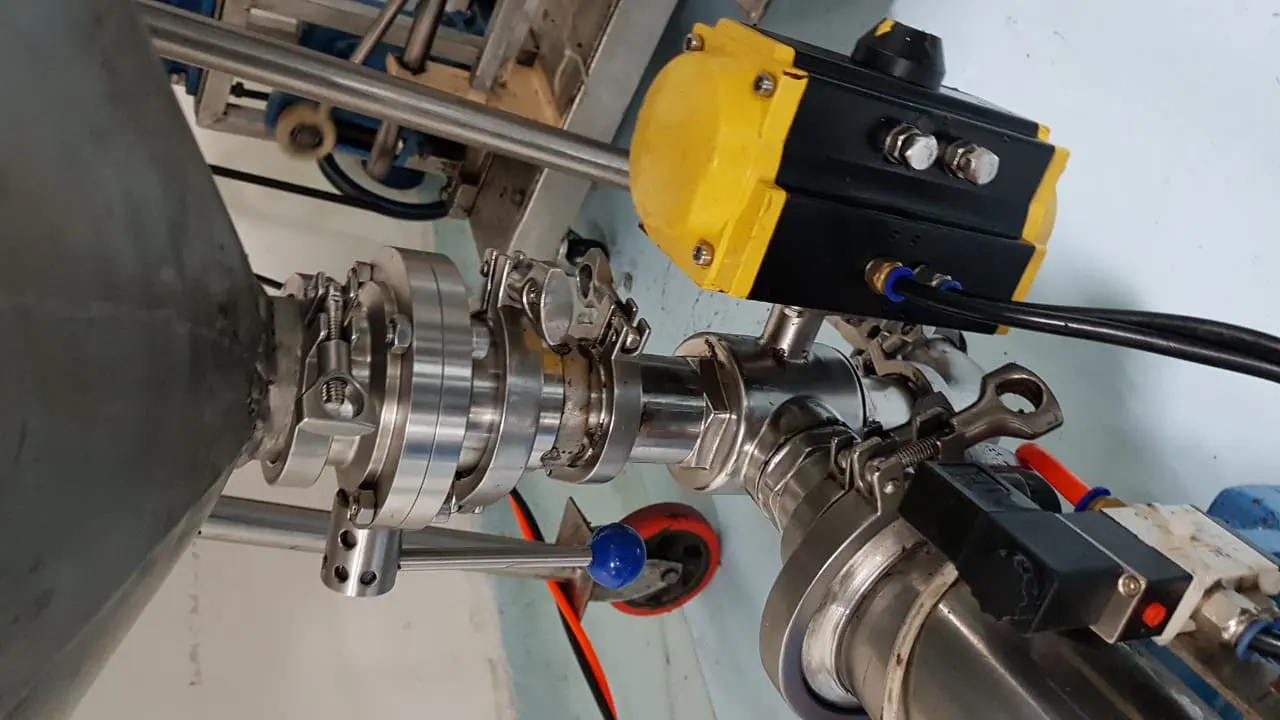

Pneumatic ball valve is composed of double (single) acting pneumatic piston actuator and floating ball valve. Learning the advantages and specifications of pneumatic ball valves will help us to better choose pneumatic ball valves. COVNA high pressure pneumatic actuated ball valve has the characteristics of compact structure, small size, reliable operation, good sealing performance and easy maintenance.

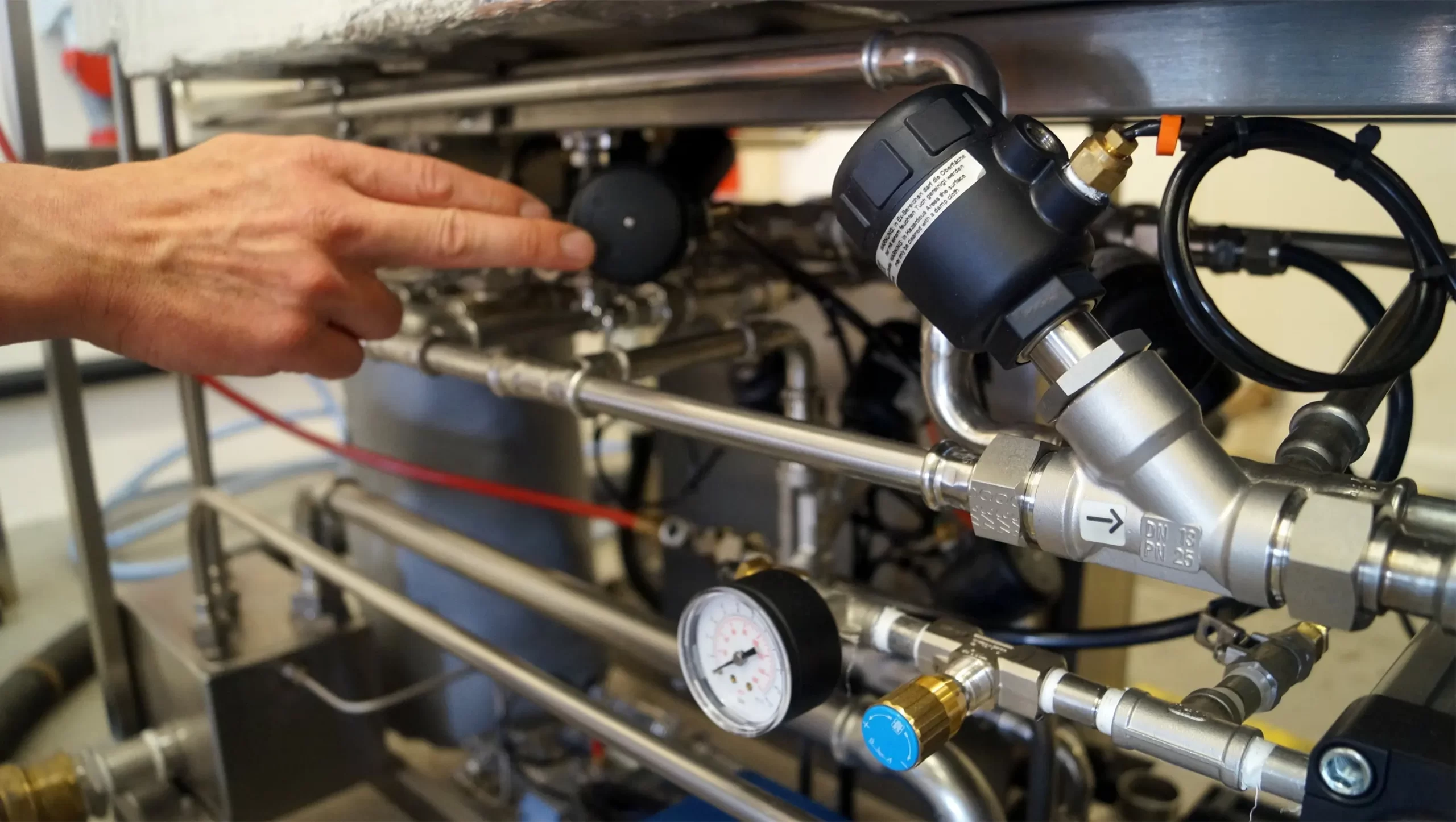

Pneumatic actuated ball valve is widely used in industrial automatic control systems such as petroleum, chemical, light industry, pharmacy, papermaking, etc. Pneumatic ball valve is mainly used to cut off or connect the medium in the pipeline. It can also be used for fluid adjustment and control. Compared with other valve types, pneumatic ball valve has angular stroke output torque, opens quickly, is stable and reliable, and is widely applicable, etc. Here are some advantages.

1. The fluid resistance is small, and the pneumatic ball valve has the smallest fluid resistance in all valve categories.

2. The thrust bearing reduces the friction moment of the valve stem, which can make the valve stem operate smoothly and flexibly for a long time.

3. The valve seat has good sealing performance. The sealing ring made of PTFE and other elastic materials is easy to seal, and the valve sealing capacity of the pneumatic ball valve increases with the increase of the medium pressure.

4. The valve stem is reliable in sealing. Because the valve stem is only used for imitating rotation, the packing seal of the valve stem is not easy to break and the sealing capacity increases with the increase of the pressure of the medium.

5. Since materials such as polytetrafluoroethylene have good self-lubricating properties and small friction loss with the ball, the pneumatic ball valve has a long service life.

6. The bottom-mounted valve stem and the convex step of the valve stem head prevent the valve stem from spraying out. If the fire causes the valve stem seal to be damaged, to ensure the valve stem seal.

7. Anti-static function: Set a spring between the ball, valve stem and valve body to export the generated static electricity.

The air actuated ball valve itself has a compact structure, reliable sealing, simple structure and convenient maintenance. The sealing surface and the spherical surface are often in a closed state, which is not easy to be eroded by the medium. It is easy to operate and maintain. It is suitable for general working media such as water, solvent, acid and natural gas. It is also suitable for media with harsh working conditions, such as oxygen, hydrogen peroxide, methane and ethylene, and is widely used in various industries. The ball valve is mainly used to cut off, distribute and change the flow direction of the medium in the pipeline. It only needs to rotate 90 degrees and a small torque can be closed tightly. Ball valves are most suitable for use as on-off and shut-off valves, but recent developments have designed ball valves to throttle and control flow, such as V-shaped ball valves. The valve body of the ball valve can be integral or combined.

Specifications of pneumatic actuated ball valve:

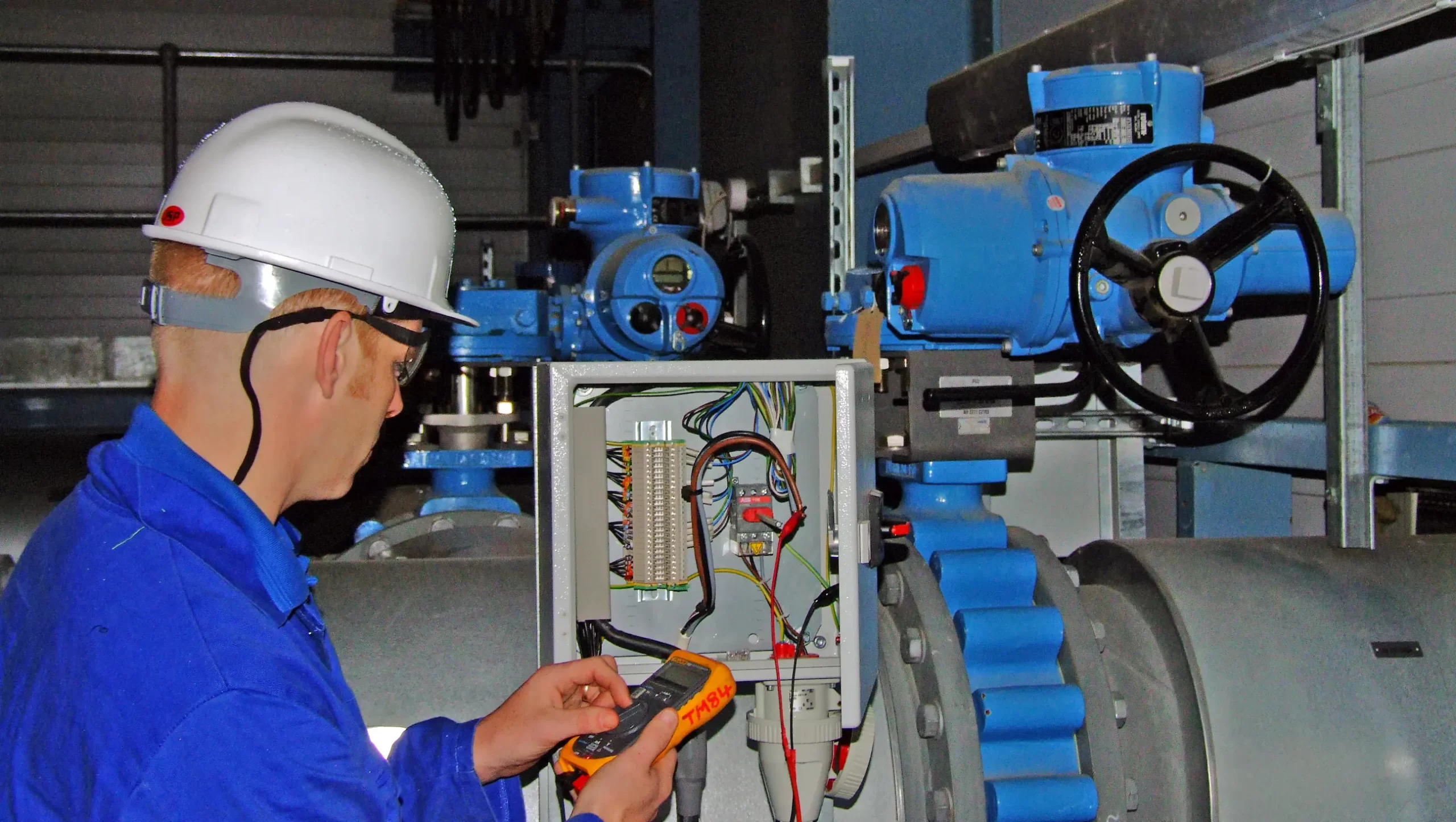

WCB, ZG1Cr18Ni9Ti, ZG1Cr18Ni12Mo2Ti, CF8 (304), CF3 (304L), CF8M (316), CF3M (316L), Ti. Different materials are used, which can be applied to various media such as water, steam, oil, nitric acid, acetic acid, oxidizing medium, urea, etc. Commonly used specifications of air source ball valves are QJQY1, QGQY1, etc. The air source ball valve is a ball valve with a pneumatic actuator. The execution speed of the pneumatic actuator is relatively fast, the fastest switching speed is 0.05 seconds/time, so it is usually called a pneumatic quick-cut ball valve. Pneumatic ball valves are usually equipped with various accessories, such as solenoid valves, air source treatment triples, limit switches, positioners, control boxes, etc., to achieve local control and remote centralized control. The valve can be controlled in the control room. , There is no need to go to the scene or high altitude and dangerously bring manual control, which greatly saves human resources, time and safety. Its working principle is to make the valve unblocked or blocked by rotating the valve core. The pneumatic ball valve switch is light, small in size, can be made into a large diameter, reliable in sealing, simple in structure, convenient in maintenance, the sealing surface and the spherical surface are often closed, and it is not easy to be eroded by the medium. It is widely used in various industries.

COVNA, a +20 years pneumatic ball valve manufacturer, offers various types of ball valve with pneumatic actuator:

- Connection types: flanged/thread/welding/tri clamp/true union

- No. of Ways: 2 way, 3 way, 4 way, stainless steel, cast iron, pvc material.

- Size: 1/4in~8in

- Pressure Range: 1.0MPa to 2.5MPa

- Applicable media: Water, oil, Gas, Liquid, steam, powder, anti-corrosive base

Addiatioal accessories: Positioner, limit switch, F.R.L, solenoid valve, handle wheel.

--- END ---