BLOG

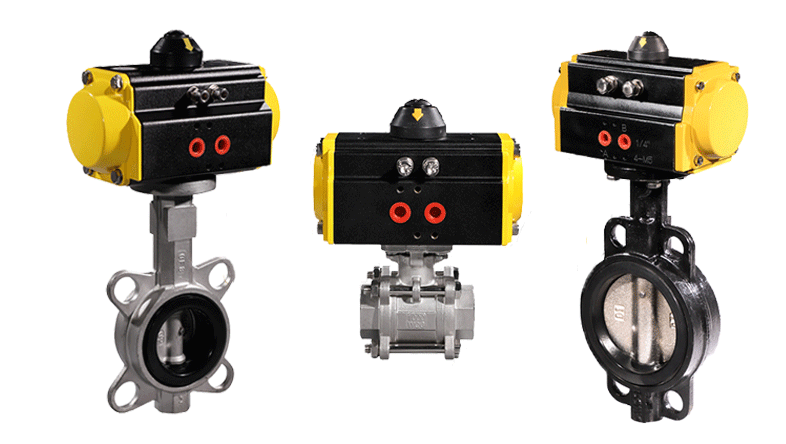

When installing or using pneumatic valves, you may encounter some problems. Here we, COVNA, bring you the solutions to the common failures of pneumatic valves.

- Pneumatic Valve Can Not Move

Possible reason:- The electromagnetic valve is normal, Coil is bumed, electromagnetic valve ls stuck being stolen.

Solution: Solenoid valve replacement, Replacement coils, remove stolen Property. - A separate air supply pneumatic Actuator test check seals and Whether the cylinderis damaged.

Solution: Replace a bad ring and cylinder. - There are impurities in the spool Valve stuck.

Solution: Remove impurities, replace Damaged parts. - The handle in a manual hand motor location.

Solution: Interchange.

- The electromagnetic valve is normal, Coil is bumed, electromagnetic valve ls stuck being stolen.

- Slow Motion, Crawling

Possible reason:- Supply pressure is not enough.

Solution: The increase of gas supply pressure(0 4-0.7mpa). - Pneumatic actuator output torque is Too small.

Solution: Increase the pneumatic actuator Production. - The valve spool or valve assembly too tight.

Solution: Re-assembly adjustments. - Air supply pipe plug, flow is too small.

Solution: Exclude plug, replace the filter cartridge.

- Supply pressure is not enough.

- Reply Devices Without Signal.

Possible reason:- Power line short circuit or open circuit.

Solution: Maintenance of power lines. - Reply within the cam position is not accurate.

Solution: Adjust the cam to the correct location. - Micro switch damaged.

Solution: Replacement micro switch.

- Power line short circuit or open circuit.

Tags: pneumatic valve

--- END ---