Introduction:

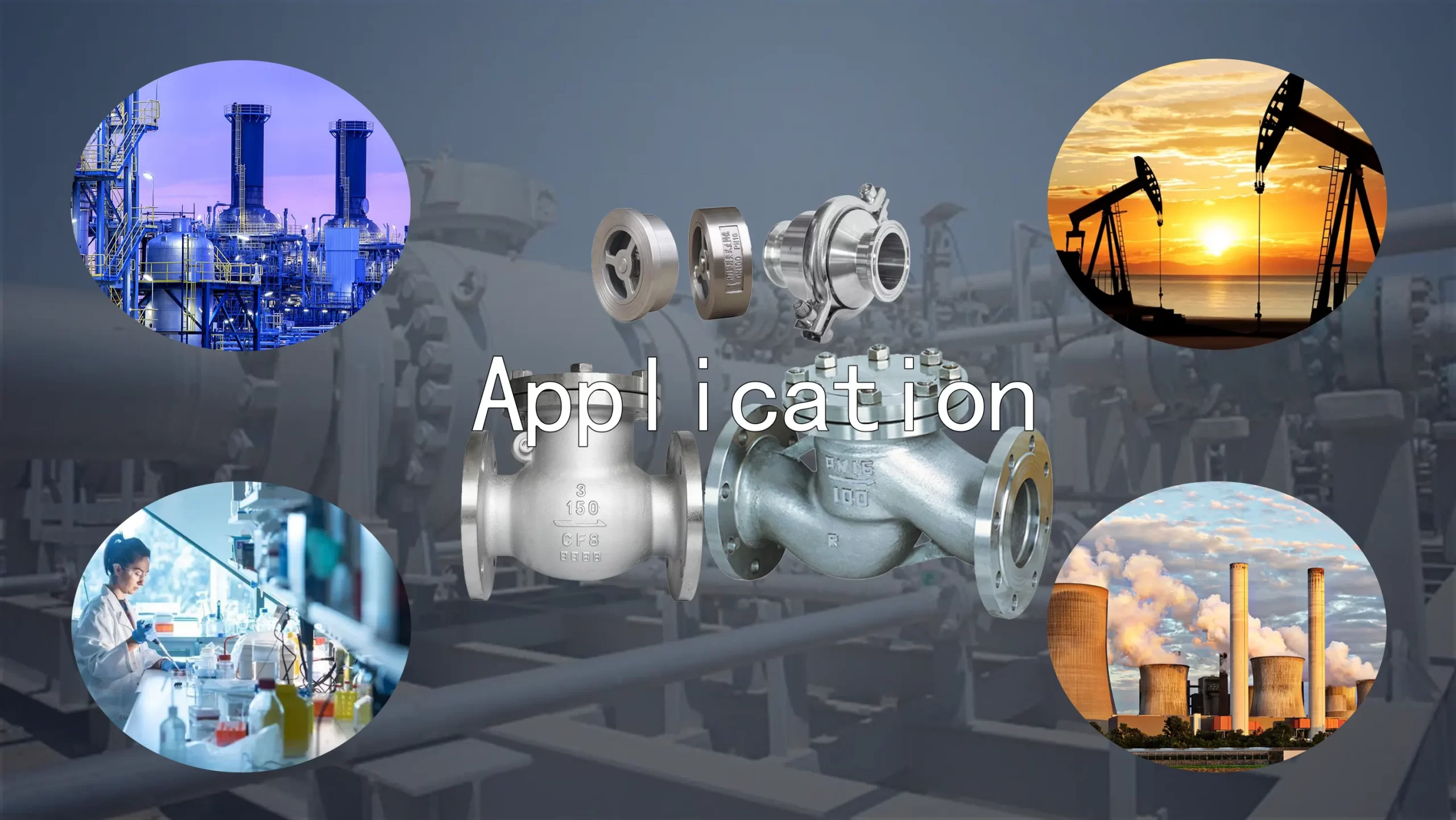

Check valves, also known as non-return valves or one-way valves, are essential components used in various industries to regulate the flow of fluids or gases in a single direction. These valves play a crucial role in preventing backflow, which can cause damage to equipment, disrupt processes, or compromise safety. In this article, we will explore the industry applications of check valves and highlight their significance in different sectors.

- Oil and Gas Industry:

Check valves are extensively used in the oil and gas industry to ensure the smooth and uninterrupted flow of fluids in pipelines. They prevent the backflow of oil, gas, or other fluids, which can lead to contamination, equipment damage, or accidents. Check valves are commonly found in oil refineries, petrochemical plants, and natural gas distribution systems. - Water Treatment and Distribution:

In water treatment plants and distribution systems, check valves are vital for maintaining the desired flow direction. They prevent the backflow of contaminated water, chemicals, or sewage into the clean water supply, ensuring the safety and quality of drinking water. Check valves are also used in irrigation systems to regulate the flow of water and prevent water hammer, a phenomenon that can damage pipes and equipment. - HVAC Systems:

Heating, ventilation, and air conditioning (HVAC) systems rely on check valves to control the flow of refrigerants, air, or water. These valves allow the desired flow in one direction while preventing backflow, ensuring efficient operation and preventing damage to HVAC components. Check valves are commonly used in heat exchangers, chillers, and air handling units. - Power Generation:

Check valves play a critical role in power generation facilities, including thermal power plants, nuclear power plants, and renewable energy systems. They are used to regulate the flow of steam, water, or other fluids in turbines, boilers, and condensers. By preventing backflow, check valves help maintain system efficiency, prevent damage, and ensure the safety of personnel. - Pharmaceutical and Food Processing:

In pharmaceutical and food processing industries, maintaining hygiene and preventing cross-contamination is of utmost importance. Check valves are used to control the flow of fluids, gases, or ingredients in production lines, ensuring that there is no backflow that can compromise product quality or introduce contaminants. These valves are commonly found in processing equipment, filling machines, and packaging lines. - Automotive and Aerospace:

Check valves are employed in automotive and aerospace applications to control the flow of fuel, oil, or hydraulic fluids. They prevent backflow, ensuring that fluids move in the intended direction and preventing damage to critical components. Check valves are commonly used in fuel systems, braking systems, and hydraulic systems in vehicles and aircraft.

Conclusion:

Check valves are indispensable components used across various industries to regulate fluid and gas flow in a single direction. Their ability to prevent backflow ensures the safety, efficiency, and integrity of processes and equipment. From oil and gas to water treatment, HVAC systems to power generation, and pharmaceutical to automotive industries, check valves find wide-ranging applications. Their importance in maintaining flow control and preventing backflow cannot be overstated, making them an essential part of many industrial processes.

Tags: Check Valve

--- END ---