Valves are essential components for regulating fluid flow and pressure in many industrial applications. Two popular types of valves are electric valves and pneumatic valves, which use different mechanisms to control fluid flow. In this article, we will discuss the use cases and advantages of each type of valve.

Electric Valves

Electric valves are powered by electricity and are controlled by an electric motor or solenoid, which opens or closes the valve. These valves are widely used in applications where precise control of fluid flow and pressure is required. Some common applications of electric valves include:

Water Treatment: In water treatment plants, electric valves are used to control the flow and pressure of water through pipes, pumps, and filters. These valves ensure that the water is treated at the optimal rate and pressure for maximum efficiency and effectiveness.

HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, electric valves are used to regulate the flow and pressure of refrigerant fluids. By controlling the flow of refrigerant, these valves can regulate the temperature and humidity of indoor environments.

Chemical Processing: In chemical processing plants, electric valves are used to control the flow of various chemicals through pipelines and reactors. By precisely regulating the flow of chemicals, these valves can ensure maximum efficiency and safety.

One of the key advantages of electric valves is their accuracy and ease of automation. These valves can be programmed to open and close within specific parameters, providing precise control over fluid flow rates and pressures. They are also highly reliable, as they require minimal maintenance and can be programmed to operate automatically, minimizing the risk of human error.

Pneumatic Valves

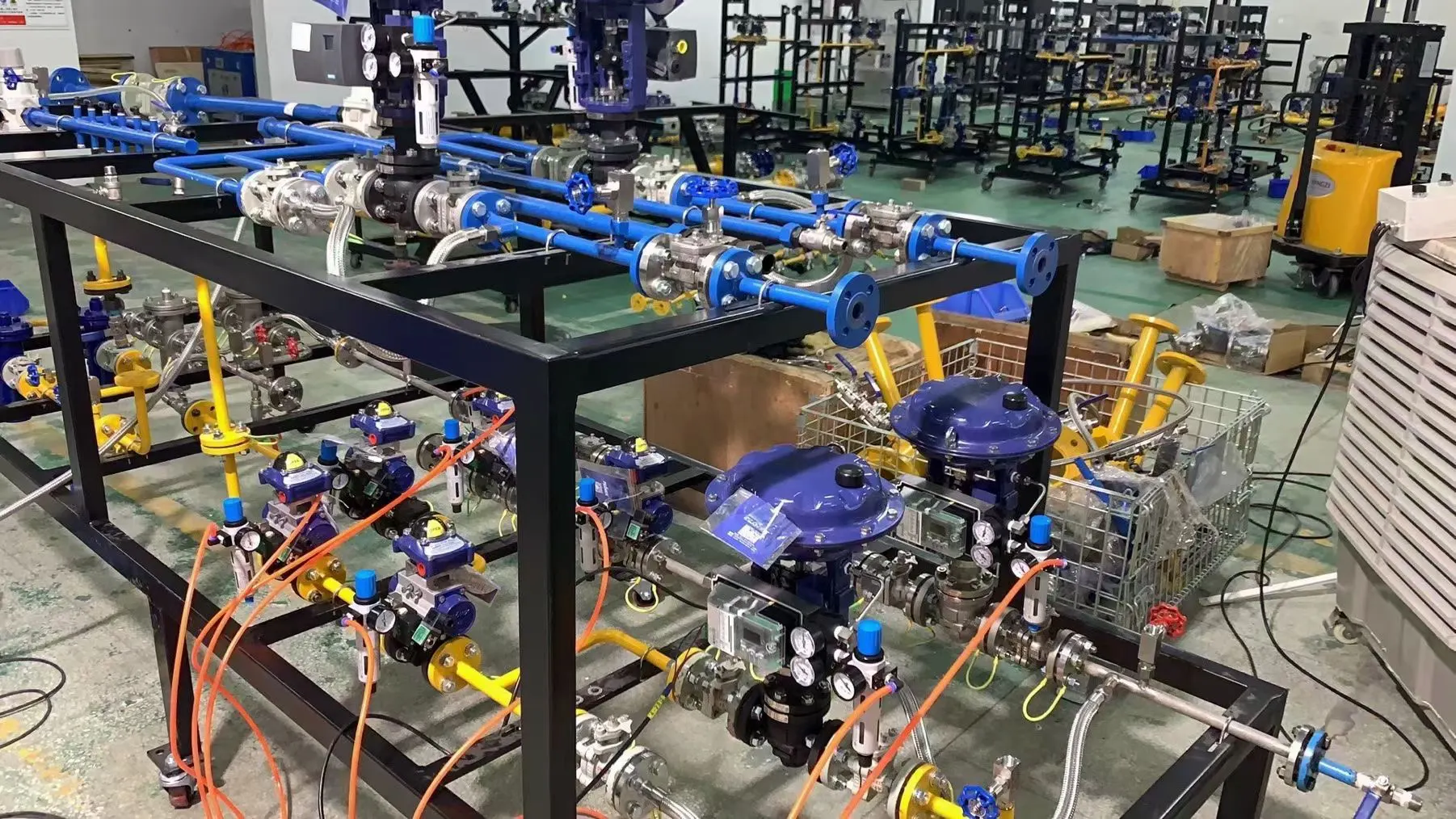

Pneumatic valves, also known as air-operated valves, use compressed air to control fluid flow. These valves are commonly used in applications where electricity is not readily available or where flammable materials are present. Some common applications of pneumatic valves include:

Oil and Gas Industry: In the oil and gas industry, pneumatic valves are used to control the flow and pressure of oil and gas through pipelines and wellheads. These valves are ideal for use in hazardous environments where the use of electricity would be dangerous.

Chemical Processing: In chemical processing plants, pneumatic valves are used to regulate the flow of various chemicals through pipelines and flow.

One of the advantages of pneumatic valves is better safety and reliability than electric valves, and it is also easy to maintain

The above are some descriptions about the application scenarios of electric valves and pneumatic valves. If you want to know more, please contact us

Tags: Motorized valve, pneumatic valve

--- END ---